When most people think of CBS ArcSafe, they think of arc flash safety — and for good reason. Remote racking and remote switching solutions have transformed how electrical workers perform potentially dangerous tasks, allowing them to stay safely outside the arc flash boundary.

But remote operation doesn’t have to stop there. At CBS ArcSafe, we’re helping facilities take the next step: using remote technology to improve the safety, efficiency, and convenience of everyday operations — not just the hazardous ones.

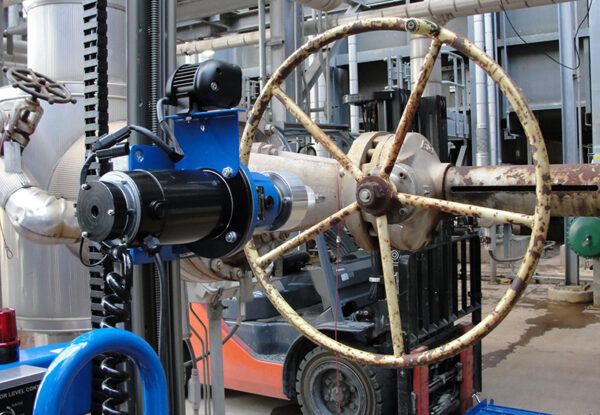

Case Study: Custom Actuator Retrofit

Every facility has tasks that require workers to approach energized or hard-to-access equipment: operating a motor starter in a tight space, flipping a disconnect tucked behind machinery, or adjusting controls on an outdoor panel exposed to the elements.

These may not be classified as high risk, but they can still pose challenges — from ergonomic strain to exposure to noise, heat, or weather. That’s where CBS ArcSafe’s custom-engineered remote operation solutions come in.

In a recent project for a major OEM in the electrical equipment industry, our team engineered a custom actuator to allow remote operations of equipment. The application didn’t involve a traditional arc flash hazard — it was about giving operators a better, safer way to perform routine work.

Multiple times a day at the customer’s site, workers were required to manually turn a large valve handwheel requiring about 110 ft-lb of torque to confirm proper function. This repetitive motion raised understandable ergonomic and safety concerns. Even though this wasn’t a typical arc flash application, it was in our wheelhouse. We understand how to replicate human interaction with switchgear.

The solution involved a trolley-based remote operating system with integrated height adjustment, powered by Milwaukee M18 REDLITHIUM battery packs. It allows operators to safely and efficiently cycle each mechanism without risk of injury or fatigue. Specifically, we improved operator ergonomics, reducing shoulder strain during repetitive mechanical testing.

By integrating a remote actuator with existing hardware, CBS ArcSafe helped the customer minimize downtime, reduce manual intervention, and simplify day-to-day operation. It’s a perfect example of how a custom solution can deliver real-world value — even outside potentially dangerous electrical switching.

Your Remote Operations Partner

Our engineers can design and build systems that remotely operate virtually any device, whether it’s a motor control center, switch, handwheel, or type of mechanical actuator. The goal is to make everyday operations safer and more efficient by letting workers control equipment from a safe distance.

Every facility is unique, and so are the challenges that come with operating and maintaining electrical equipment. Whether you need to keep workers clear of a potential hazard or simply make routine tasks easier to manage, CBS ArcSafe can help.

Our engineering team specializes in custom retrofits, actuators, and control systems that bring remote operation to existing and new applications — helping you enhance safety, save time, and improve consistency across your operation.

If you can imagine a task you’d like to perform remotely, chances are we can design the solution. Contact us to enhance safety at your facility, from arc flash mitigation to everyday performance.