OSHA Arc Flash Safety Regulations

All You Need to Know About OSHA and Arc Flash Safety

With the increase in awareness of the severity and frequency of electrical arc flash hazards, OSHA realized the need to provide more direction and regulation to its general language. The result was a final rule to 29 CFR 1910.269, the Electrical Power Generation, Transmission, and Distribution Standard which became effective on July 10, 2014. This was the first time OSHA mandated specific arc flash related requirements which go beyond general hazard awareness and also set mandatory compliance deadlines. At CBS ArcSafe, safety of our customers’ electrical workers is our top priority. In order to achieve this goal, CBS ArcSafe stays informed about current and new requirements from both the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA).

What is an arc flash?

An arc flash is a phenomenon where a flashover of electric current leaves its intended path and travels through the air from one conductor to another, or to ground. The results are often violent and when a human is in close proximity to the arc flash, serious injury and even death can occur.

What can cause an arc flash?

- Dust

- Mishandling of tools

- Accidental contact

- Condensation

- Equipment/material failure

- Corrosion

- Faulty installation

- Lack of maintenance

- Voltage transients

What can result from an arc flash?

- Burns

- Fire

- Flying objects

- Blast pressure (upwards of 2,000 lbs./s.f.)

- Sound blast (upwards of 140 dB)

- Extreme heat (upwards of 35,000 degrees F)

How to protect workers from arc flash:

- De-energize the circuit

- Energized electrical work permit

- Personal protective equipment

- Insulated tools

- Written safety program

- Job briefing

- Isolate workers with remote racking and switching

- Preventive maintenance and testing

- Incorporate engineered methods for energy reduction, such as:

- Maintenance switches

- Zone selective relays

- High resistance grounding

- Arc resistant switchgear

What questions will OSHA ask you when an arc flash has happened at your facility?

- Is there a description of the circuit or equipment at the job location?

- Is there a detailed job description of planned work?

- Can you justify why equipment cannot be de-energized or the job deferred until the next scheduled outage?

- Were the workers performing the tasks qualified to do so?

- Was the faulty equipment maintained in accordance with your electrical maintenance plan (EMP)?

- Was the job performed in accordance with your electrical safety plan?

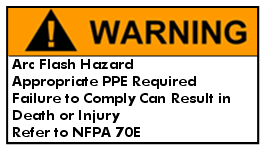

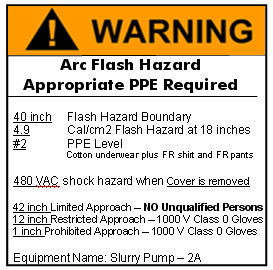

What is the arc flash warning label?

An evaluation of arc flash and shock protection needs to be performed on each piece of equipment operating at 50 volts or more and not put into a de-energized state. The evaluation will determine the actual boundaries (i.e. prohibited, limited, restricted, etc.) and will inform the worker of what personal protective equipment must be worn.

An Arc Flash Hazard warning label must be affixed to the equipment once the evaluation is completed. This label must be readily accessible to employees who may work on the energized equipment.

Minimum arc flash label example

Preferred/detailed arc flash label example

OSHA Arc Flash Violation Samples

View OSHA News Releases here.

May 28, 2024 – Department of Labor cites leading tool, equipment manufacturer after maintenance electrician suffers severe burns in electrical arc fire

January 31, 2023 – Federal investigation into fatal 2022 electrocution in Kansas City finds Midwest engineering services company again failed to protect workers

January 12, 2023 – US Department of Labor cites Eversource Energy Service Co. for willful, serious violations after fatal Beacon Hill arc flash, blast in Boston

August 1, 2022 – US Department of Labor proposes $480K in additional fines to Ohio vehicle parts manufacturer for continuing to expose workers to multiple hazards

June 28, 2019 – Hudapack Metal Treating of Illinois, Inc., based in Glendale Heights, IL, has been cited by OSHA for failure to use electrical safety work practices, provide appropriate personal protective equipment, train employees and repair damaged electrical outlets. The company faces penalties over $180,000.

June 6, 2019 – ASARCO, a metal smelting company based in Hayden, Arizona, has been cited by OSHA for electrical hazards which caused severe burns to three employees. The company faces $278,465 in proposed penalties.

February 20, 2019 – OSHA cited von Drehle Corp. for several workplace safety hazards that put employees at risk at its Natchez, Mississippi facility. The company faces over $300,000 in possible penalties.

August 6, 2018 – OSHA cited Day & Zimmerman NPS Inc. for exposing employees to electric shock hazards at the Tennessee Valley Authority Sequoyah Nuclear Power Plant in Soddy Daisy, Tennessee. The company faces $71,599 in proposed penalties.

June 1, 2018 – OSHA cited EWP Renewable Corp., doing business as Springfield Power LLC, for 25 safety violations after an employee suffered fatal injuries after he was pulled into a conveyor at the company’s Springfield plant in November 2017; proposes $125,460 in penalties.

December 21, 2017 – An electrician sustained serious burns from an arc flash while installing and testing breakers at a manufacturing plant in Fargo, N.D.

January 21, 2017 – OSHA launches inspection into incident in which one worker died and another was hospitalized in critical condition from arc flash at a construction site in Amarillo, TX.

OSHA Reports Improvements In General Electrical Compliance In 2017

OSHA released its Top 10 list of most cited violations in 2017, and violations in the General Electrical Requirements category, on the Top 10 list in previous years, weren’t on the list this year. Companies are taking electrical safety more seriously, but more can be done. CBS ArcSafe aims to eliminate arc-flash hazards with its remote racking and switching solutions. Read more.

OSHA Arc Flash Standards

- 1910.335 – Applicability of the new Electrical Safety final rule, Subpart S, to the construction industry [09/07/1990]

- 1910.335 – Clarification about 29 CFR 1910.333 and 29 CFR 1910.147 as they relate to work inside an electrical panel and on related equipment. [07/28/2006]

- 1910.335 – Letter requesting interpretation of the OSHA electrical standards as they apply to employees using insulated hand tools. [05/20/1996]

- 1910.335 – Minimally acceptable levels of illumination; Resistor banks on overhead cranes; Overhead lines; Protective gloves on energized equipment. [04/28/1992]

- 1910.335 – OSHA requirements for warning signs and protection from electric-arc-flash hazards and compliance with NFPA 70E-2004. [11/14/2006]

- 1910.335 – Relevance of NFPA 70E industry consensus standard to OSHA requirements; whether OSHA requirements apply to owners. [07/25/2003]

- 1910.335 – Use of general protective equipment and tools by employees when working near exposed energized conductors or circuit parts in the workplace. [12/27/1991]

- 1910.335 – Whether use of personal protective equipment is mandatory when working under heat stress conditions. [05/18/2010]

- 1910.335(a) – Whether use of personal protective equipment is mandatory when working under heat stress conditions. [05/18/2010]

- 1910.335(a)(1)(iv) – OSHA requirements for warning signs and protection from electric-arc-flash hazards and compliance with NFPA 70E-2004. [11/14/2006]

- 1910.335(a)(1)(v) – OSHA requirements for warning signs and protection from electric-arc-flash hazards and compliance with NFPA 70E-2004. [11/14/2006]

- 1910.335(a)(2)(i) – OSHA requirements for warning signs and protection from electric-arc-flash hazards and compliance with NFPA 70E-2004. [11/14/2006]

- 1910.335(a)(2)(i) – Training and PPE for employees performing tests on equipment. [06/22/1998]

- 1910.335(a)(2)(i) – Use of insulated hand tools. [07/30/1996]

- 1910.335(a)(2)(ii) – OSHA requirements for warning signs and protection from electric-arc-flash hazards and compliance with NFPA 70E-2004. [11/14/2006]

- 1910.335(a)(2)(ii) – Use of ANSI C2-1997 as guidance for protecting employees working near insulated shielded conductors. [09/26/2002]

- 1910.335(b) – OSHA requirements for warning signs and protection from electric-arc-flash hazards and compliance with NFPA 70E-2004. [11/14/2006]

- 1910.335(b)(1) – OSHA requirements for warning signs and protection from electric-arc-flash hazards and compliance with NFPA 70E-2004. [11/14/2006]